There are many modes to ship your freight either down the street or across the globe. The mode you pick can be determined by many factors, including the products you sell (e.g. perishables or non-perishables), supplier production lead times, product availability, customer lead times, source of supply (i.e. US or abroad), customs and excise rules (i.e. duty or quarantine), volume, and more. Each method has its own advantages and disadvantages and choosing the wrong method can cost you more time and money than is necessary. Take a look at some of the most popular shipment modes to see if you could increase your savings and efficiency.

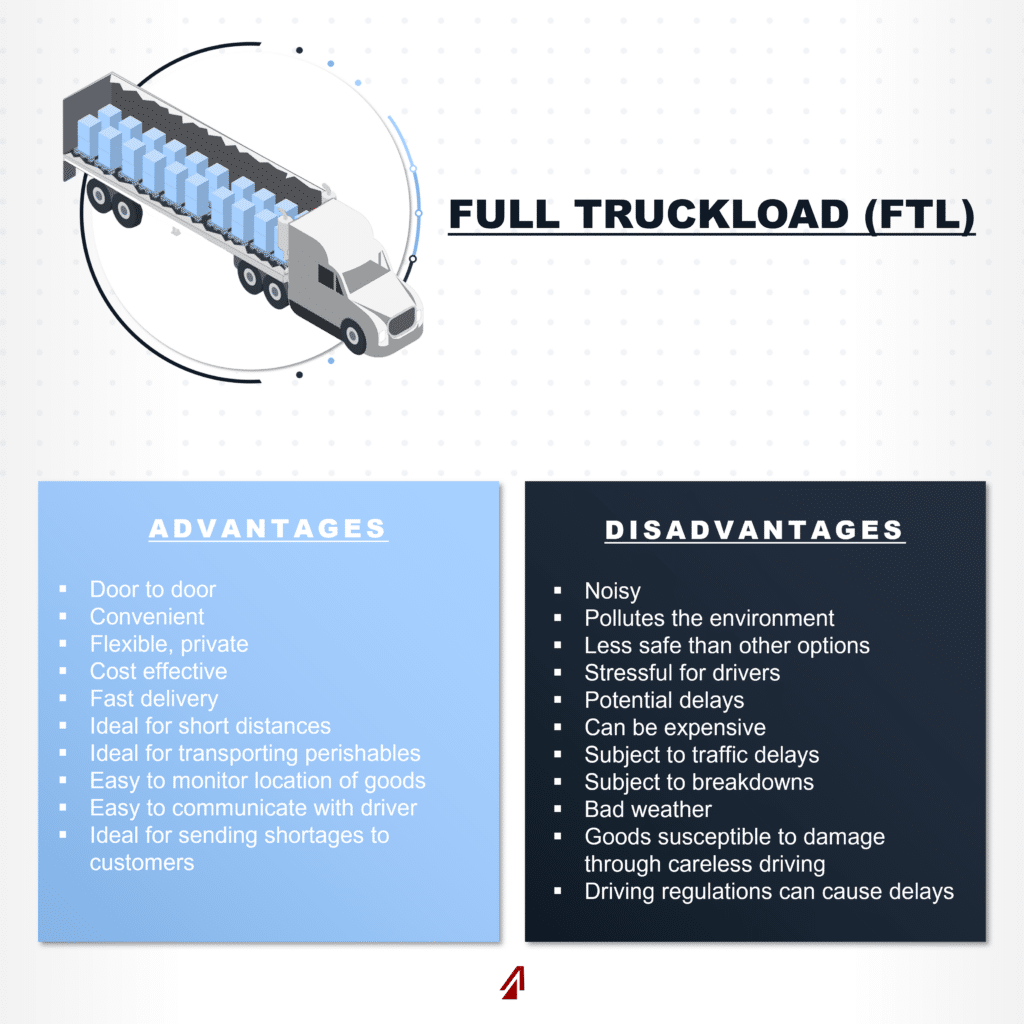

Full-Truckload (FTL)

The first is the most common shipping method for ground transportation across North America. Full-Truckload is when a shipment utilizes an entire trailer (i.e. a 53 ft dry van, reefer, flatbed, etc.). For a typical shipment, a driver is contracted to arrive at a certain time, pickup a shipment, and deliver the freight directly. This method is great for larger quantities or greater volume shipments, larger or heavier items, or shippers that require more security. Other advantages include speed of delivery, no handling of the freight in transit, and specific shipping or delivery days and times.

The greatest disadvantage is cost. Many shipments are smaller than a full-truckload, and these leave the trailer underutilized. All of that to say that the customer is paying for more than they need. Also, there are times when a shipment does not need to be delivered at a specific day and time, and paying for speed is unnecessary. Using full-truckloads, when a less-than-truckload option is available, is often an area where supply chain managers overspend. See other ways LTL can help increase savings and efficiency.

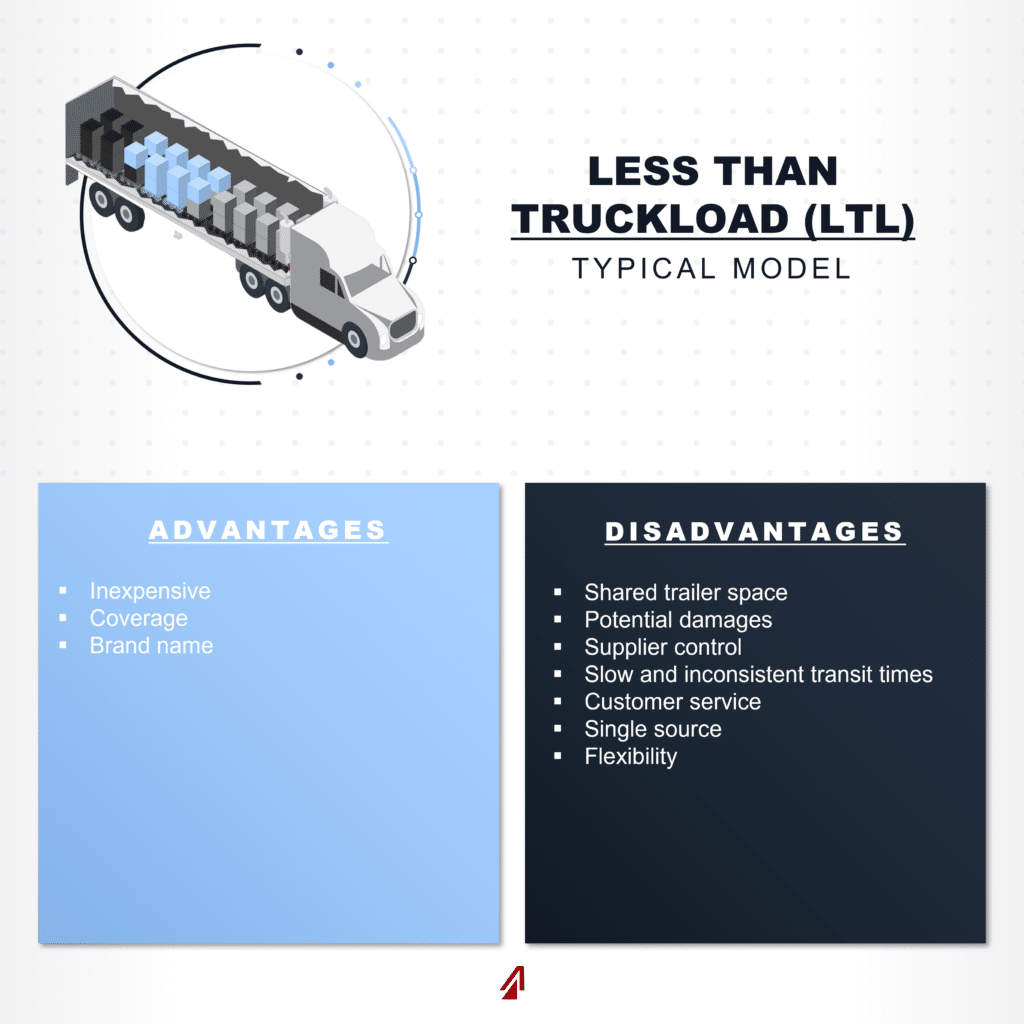

Less-Than-Truckload (LTL)

For this article, we are going to discuss the advantages and disadvantages of three specific LTL methods – traditional LTL, ProTrans LTL, and milkruns.

Traditional LTL

The first benefit to an LTL shipment is that it is cheaper than an entire truckload. Several customers utilize a trailer together and each customer pays for the space in the truck their freight uses. For a typical shipment, pickup/delivery drivers usually have set routes which they travel every day or several times a week, so the driver has an opportunity to develop a rapport with his customers. Once the driver has filled his trailer or completed his assigned route, he returns to his terminal for unloading. The trailer is unloaded and the individual shipments are then weighed and inspected to verify their conformity to the description contained in the accompanying paperwork. All LTL freight is subject to inspection for this purpose, though not all freight is inspected. Next, the freight is loaded onto an outbound trailer which will forward the freight to a breakbulk, a connection, or to the delivering terminal. An LTL shipment may be handled only once while in transit, or it may be handled multiple times before final delivery is accomplished. The major advantages to LTL are the reduced costs, and the consistency of coverage. This method is often slower, as shipments are not direct, but that might not factor in depending on a customer’s needs.

A particular disadvantage to traditional LTL include multiple freight handlings. In a typical LTL shipment, a pallet might be handled five or more times, depending on the consolidation network. That means more chances for loss or damages, longer shipment times, and greater risk. Other disadvantages include less supplier control (as shipments might be picked up only on certain days) or less flexibility.

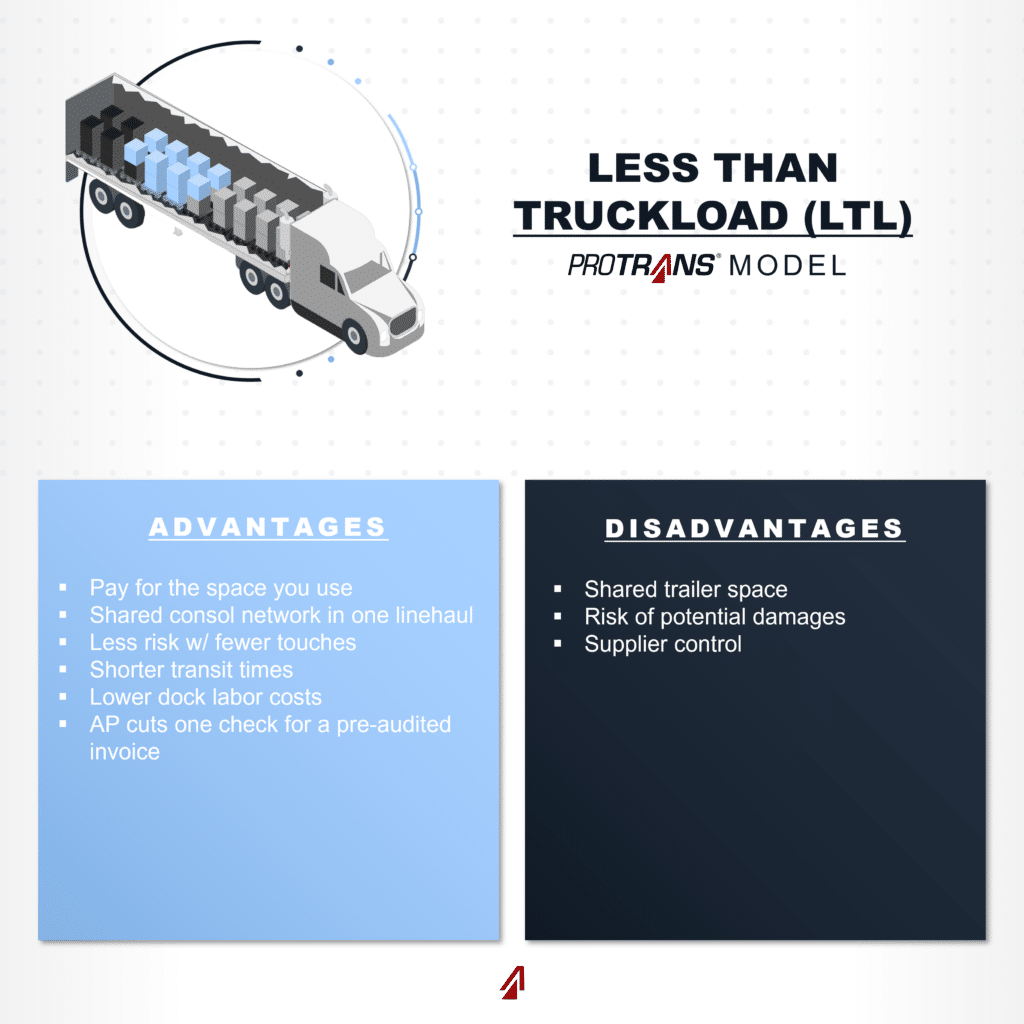

ProTrans LTL

Now, ProTrans LTL is different than traditional LTL in several ways. First, we do not use the traditional hub-and-spoke method, rather our own customized consolidation network. We have over 30 facilities across North America that we utilize to make more direct pickups, linehauls, and deliveries as well as shorter transit times. These direct runs help us reduce the risk of loss and damage to our customers’ freight. We ensure the freight is safe by reducing the amount of touches it receives, fully utilizing load bars, logistics posts, and air bags to prevent movement in the trailer, as well as securing the trailer itself with CTPAT standard locks and security checks. Overall, we offer supply chain managers significant savings through competitive shipment costs, full-trailer utilization, reduced damages, reduced dock labor costs, as well as efficient billing practices.

Disadvantages to the ProTrans LTL model are significantly reduced compared to traditional LTL models but are not entirely eliminated. Freight will still share space in a trailer and will require handling to reach its destination.

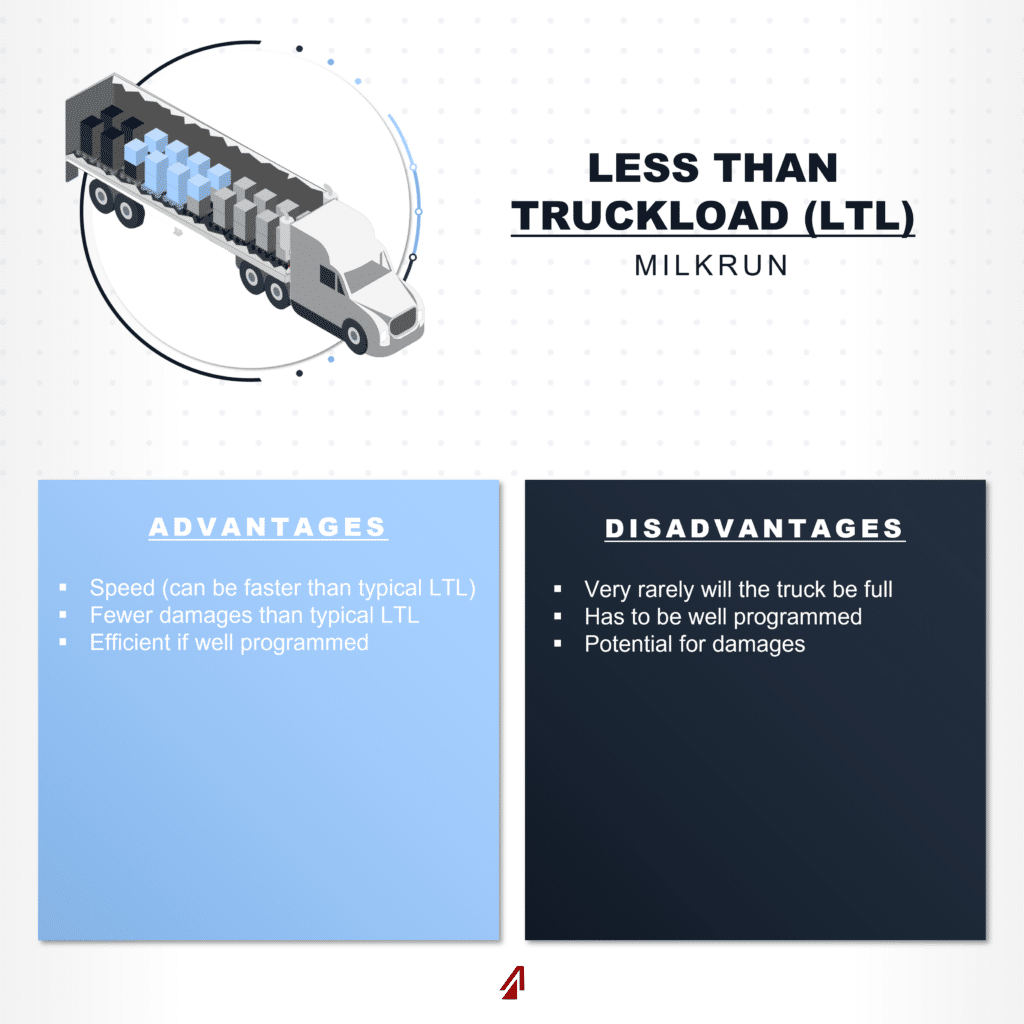

Milkruns

A milkrun gets its name from the dairy industry practice where one tanker collects milk every day from several dairy farmers for delivery to a milk processing firm. In manufacturing, Instead of each of several (say 5) suppliers sending a vehicle every week to meet the weekly needs of a customer, one vehicle visits each supplier on a daily basis and picks up deliveries for that customer. This way, while still five vehicle loads are shipped every week, each vehicle load delivers the full daily requirements of the customer from each supplier. Some advantages for milkruns include speed, efficiency, and safety for well programmed systems.

Disadvantages for milkruns include underutilization, excessive planning and execution, and a significant potential for freight damage.

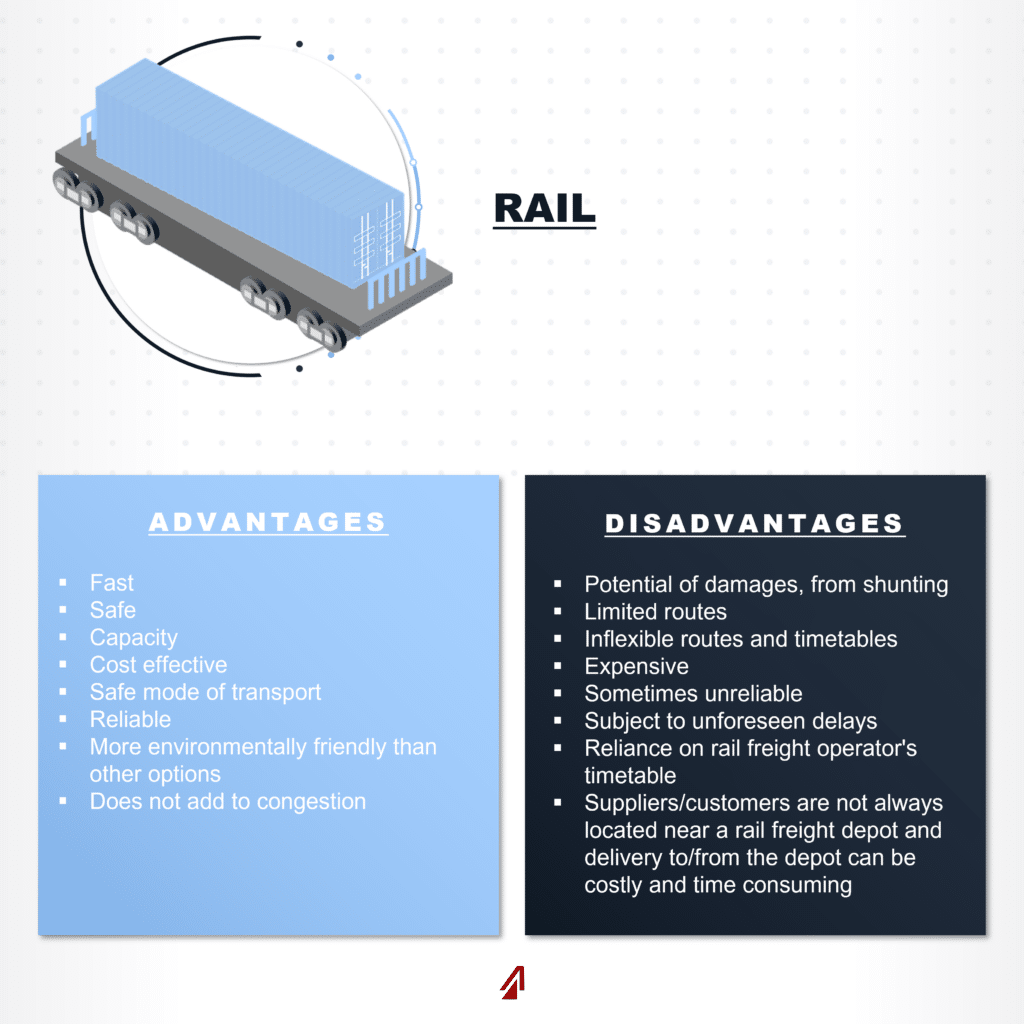

Rail

Rail is one of the older and most reliable transportation modes. It offers many advantages and is (for obvious reasons) used for domestic use or inter-continental. Businesses use rail transportation for the delivery of a wide range of goods including post, coal, steel and other heavy goods. Some of the advantages to rail include speed, safety, significant capacity, reliability, eco-friendly, and does not add to congestion on the streets or highways.

This mode also poses significant disadvantages. Rail is often limited in its routes and its terminals may not be located near shippers or customers. This mode is fairly expensive and is extremely inflexible with timetables.

Sea transportation is used by businesses for the delivery of goods from distant suppliers, who do not care about lead times. Most sea transportation is conducted in containers which vary in size. Goods can be grouped into a container (LCL) or fill a container (FCL). Sea tankers are used for bulk shipments of loose goods such as oil, grain and coal.

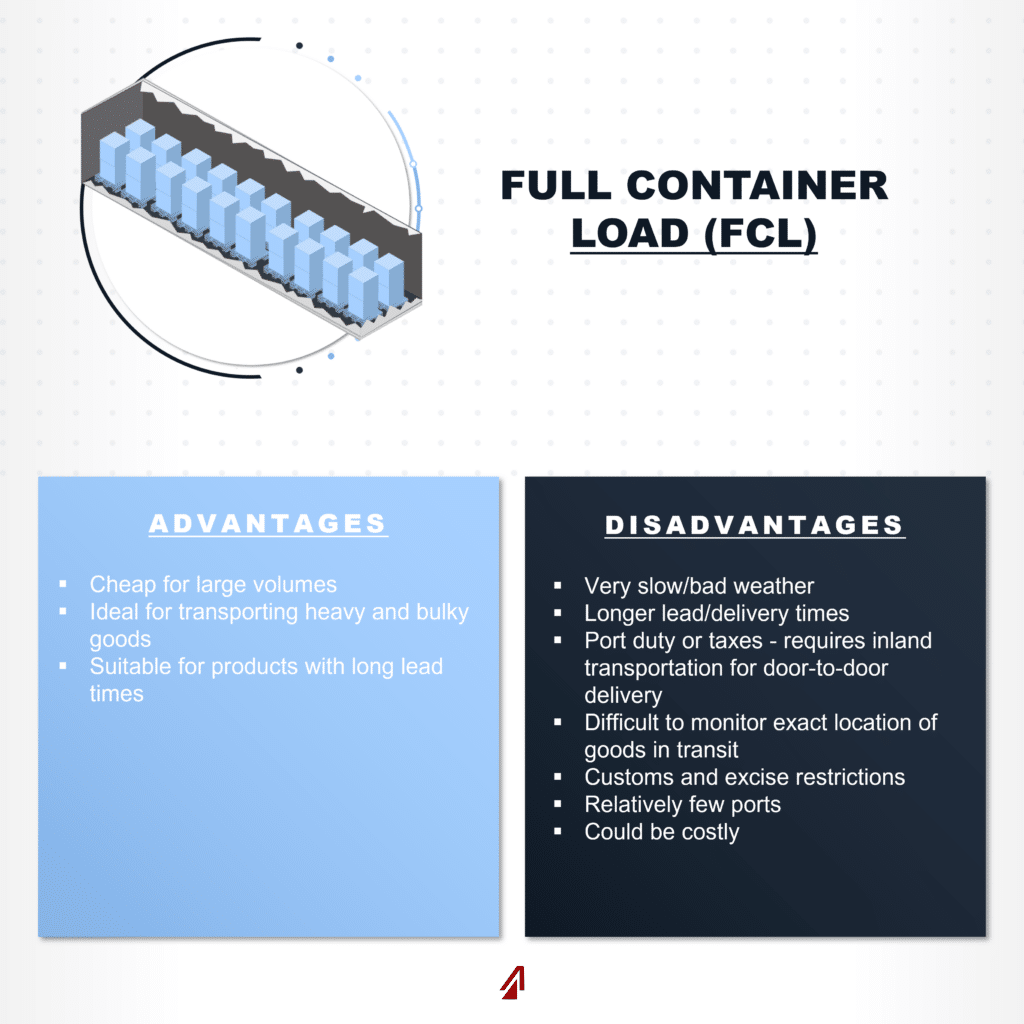

Full Container Load (FCL)

Full container loads are like their domestic counterparts, FTLs. They are exclusive to a single customer and can be ideal for shipments that require more space or security. These shipments are suitable for freight with longer lead times, are cheaper for larger volumes, and are ideal for freight that is heavier or more bulky. FCL is also one of the major international shipping modes and can be more competitive than air travel.

Some of the disadvantages to FCL include much slower than alternative modes – like air travel. They require longer lead times and are more subject to inclement weather. While at sea, these shipments are more difficult to track and receive an exact location. Cost is also a significant factor with fewer freight line options/capacity, duties and taxes at port, customs restrictions, and greater risk of loss or damage.

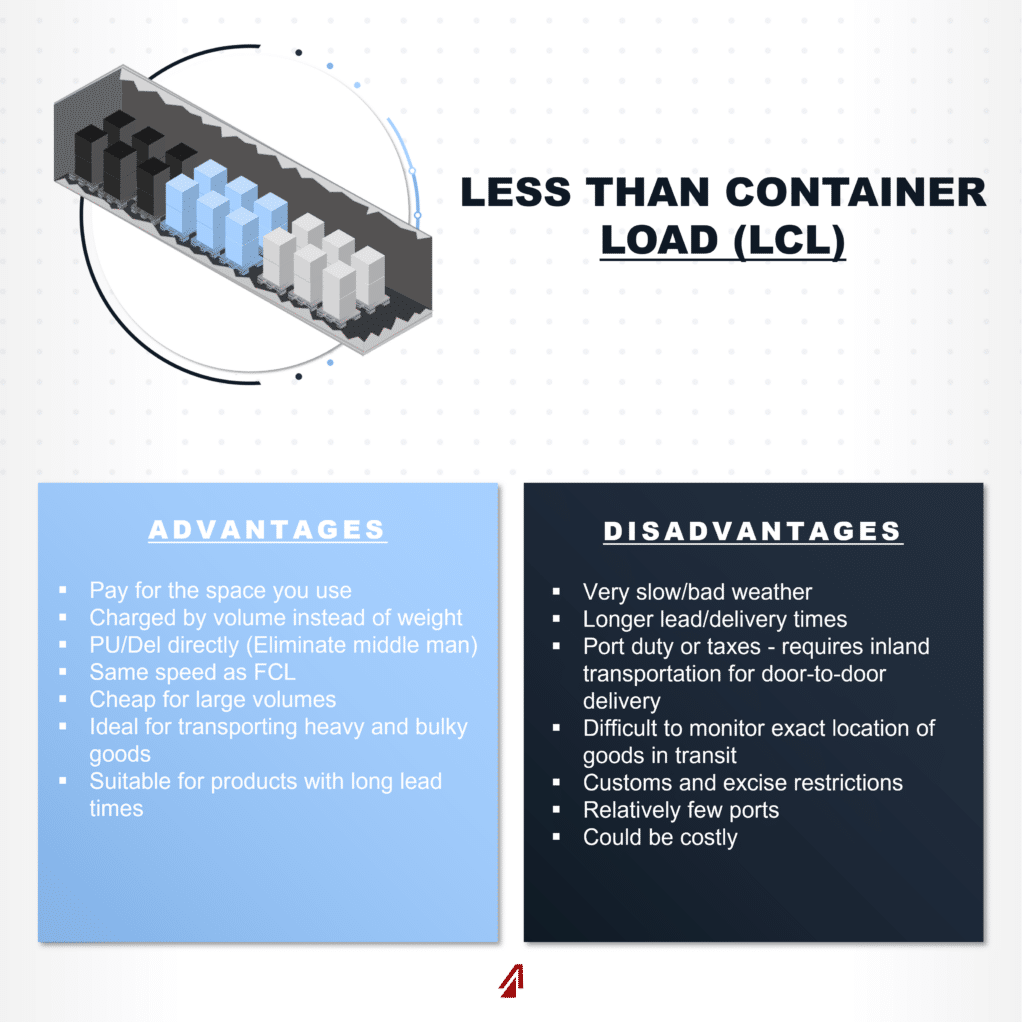

Less-than-Container Load (LCL)

LCLs are a cheaper and more efficient option for customers with less international freight to ship at a time. With LCLs, you pay for the space you use in a container and are often charged by volume, rather than by weight. Shipments can be picked up or delivered directly to/from the container yard, rather than requiring a middle man to collect and consolidate freight. They ship the same speed as FCLs and are also suitable for products with longer lead times. Freight forwarders, like ProTrans Global and TOC Logistics International, can help customer make the most of their containers with better organization and greater space utilization.

However, LCLs are subject to very similar disadvantages to FCLs.

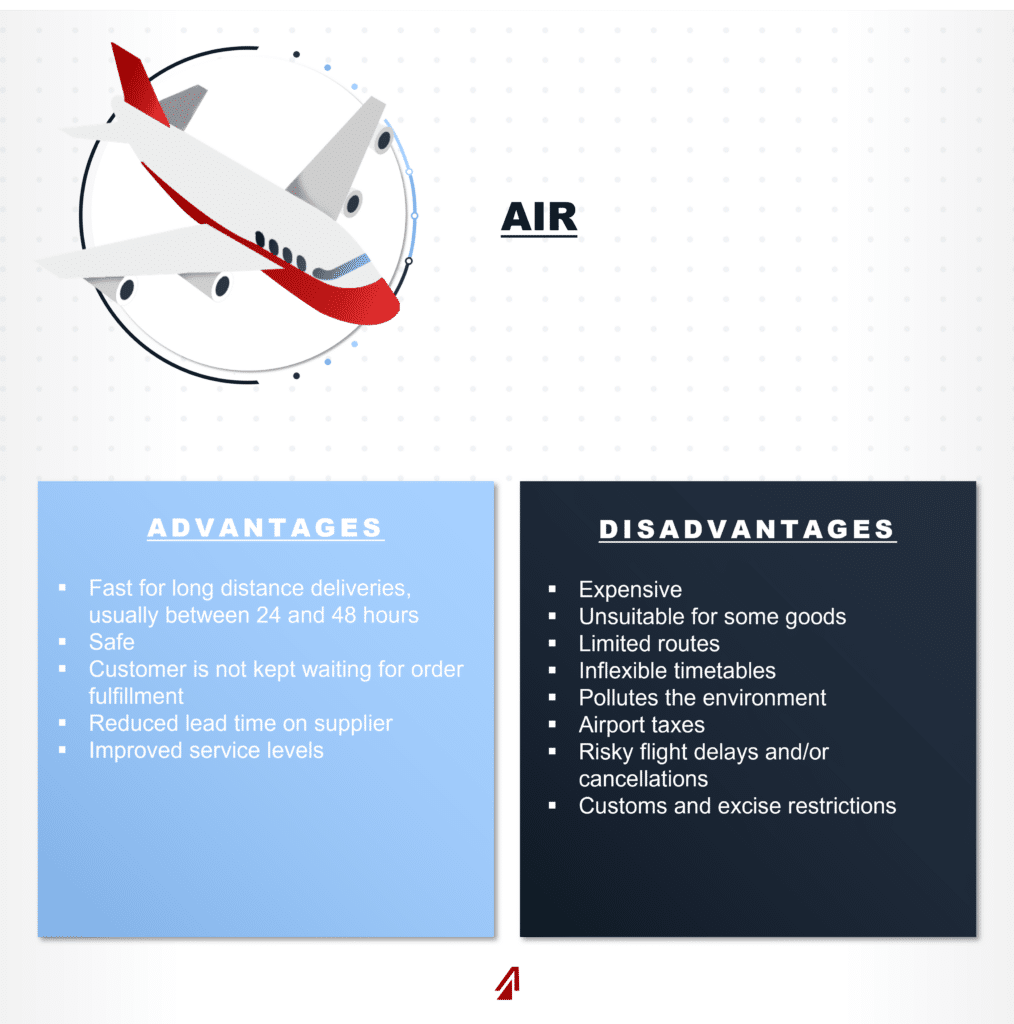

Air

Air is the final mode discussed in this article and is one of the most all-encompassing shipment methods available. It is fast, reliable, safe, relatively flexible, and can be used either domestically or internationally. It is ideal for “hot” shipments with short lead times and can handle a significant amount of weight and volume in a shipment.

The greatest disadvantage of air is the cost. Customer pay for the speed to market with their freight. Each aspect of air travel is costly, from equipment to fuel, as well as taxes, fees, customs, and other charges. In addition to high costs, air travel cannot accommodate every type of commodity or good and can be limited by size, weight, and volume. It is also limited by specific routes and timetables. Lastly, it is a large pollutant to the environment.

There are many ways to transport goods, and each mode has its advantages and disadvantages. Each mode can offer a supply chain manager greater savings or efficiency depending on their situation. Need help deciding what mode to use for your supply chain? Contact ProTrans today, and we can help find the best mode for your needs.