Operating a warehouse is one of the most complicated functions in any company’s supply chain. It involves numerous operations from shipping and receiving to stock counts and inventory. Each individual facet can be challenge, so it is vital that you remain organized. The best way to organize your data and your products, is by using a warehouse management system (WMS). These programs help you track and process your freight from the moment you receive it until it is shipped to its final destination. See how a WMS can help you and check out some top features your WMS should have.

What is a WMS?

A warehouse management system is a sophisticated software platform that manages the day-to-day functions of a warehouse. These can usually be found as a part of enterprise resource planning (ERP) suite or as a standalone program. The system is centrally managed and offers control over each aspect of the warehousing process; including:

• Warehouse Layout

• Receiving

• Stocking

• Tracking

• Order Fulfillment

• Shipping

• Inventory

• Employee Management

• & More

Overall, the main goal of a successful warehouse management system is to increase your company’s productivity and organization.

Why is a Warehouse Management System Needed?

These systems are needed to help you create better visibility and efficiency within your warehouse. A 2012 study from the American Productivity and Quality Center (APQC) shows that organizations that use WMSs are more efficient and have more accurate warehousing data. This can help with lower logistics costs and higher perfect order performance.

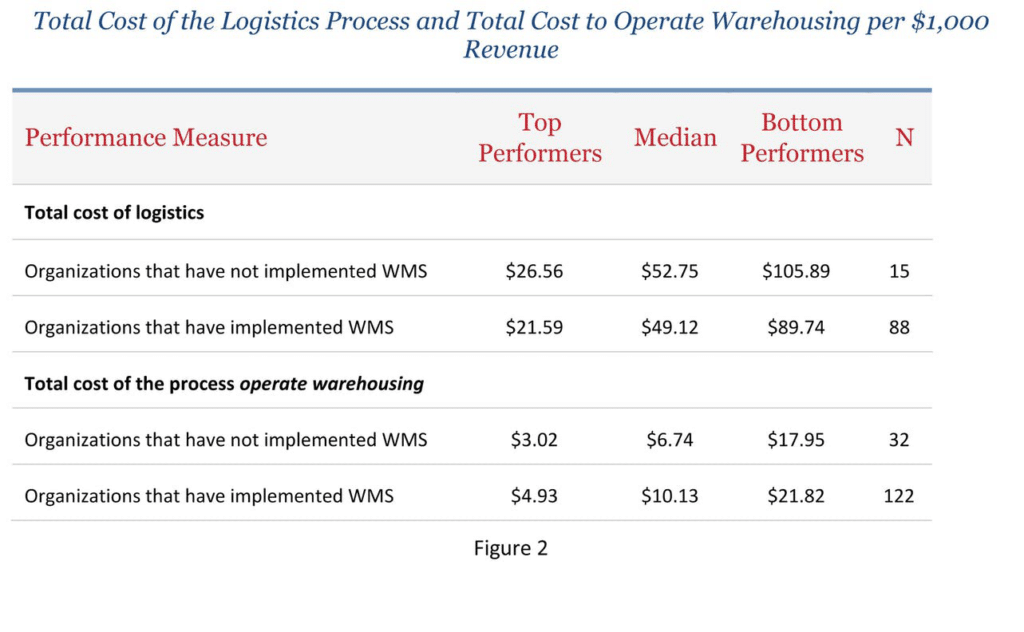

Their study showed the following data:

https://www.industryweek.com/warehousing-and-distribution/improve-efficiency-within-warehouse

This shows that that even median performing companies are averaging $3.63 savings per $1000 in revenue on their logistics costs. APQC’s data shows that warehouse operation costs rise as well, but these costs are often offset by factors like WMS package used, number of employees using WMS, and the logistics costs savings themselves. Even the poorest performing warehouses can save money by implementing a WMS. In addition to costs savings, warehouses can gain in efficiency.

According to APQC’s study, companies using a WMS have higher perfect order performance. This means that these companies deliver more orders on time, complete, and more accurately. This helps you with…

1. Higher customer satisfaction

2. Fewer expedites

3. More logistics savings

Often, these benefits come from greater visibility. You have access to a single system that can monitor each facet of the operation and can help your employees quickly find, pick, and ship products. Also, a centralized inventory system can give you a better idea of what products are available. This can help prevent shipping delays, expedites, and improve your on-time-delivery.

Warehouse management systems often perform at their peak when working in conjunction with other technologies like an ERP Suite, TMS, automated picking, and RFID.

Need help with warehouse management or logistics in general?: LEARN MORE

What are Some Functions/ Features that Make for a Top System

So, if you have decided to implement a WMS, you might be wondering where to purchase it and what type of features to look for in your system. The answer to both of these questions vary depending on the type, size, and scale of the warehouse you operate, your budget, and what features you need the most.

The majority of WMSs are highly customizable to your unique specifications. Companies like Oracle can work with you directly to create a setup specifically for you. Or, companies like Selecthub can show you multiple options side-by-side. Whichever provider you choose, look for these qualities in both your system and provider:

Maximum Functionality

Your system should…

• Be Useful – able to perform the tasks you need

• Be User-friendly – have a quick learning curve and simple menus

• Be Flexible – be compatible with your current system or ERP

• Be Scalable – grow as you do

• Provide Metrics – track what you want to know

Complete Transaction Management

• Should track each of your warehouse operations and provide useful metrics in charts and reports

Proven Track Record

• Work with a company and system that has proven to be effective and efficient for other customers

• Provider has a commitment to you and your industry and can focus on your needs as far as upgrades, developments, and expansion

Value

• Choose a system that will give you the best value even if it is more expensive. It is cheaper to buy the higher priced system, than it is to purchase a cheaper one and upgrade to the costlier one later.

It is important that work with a system and company that is reliable, functional, and specific to your needs.

As stated before, each system is unique; but there are a few things that most warehouses require in any industry. Some of these include:

• Data input and storage functions – these can be manual or automated depending on your warehouse structure. Each step of your operation generates data, so you should be able to add it to the system.

• Tracking functions – You should know when a product enters or leaves your warehouse and where it is while it is on site. You should also have the ability to track inventory quantities (IMS), customer orders (past, present, and future), replenishment orders, B.I. assignments, and employee tasks.

• Order/Fulfillment functions – know what needs to be shipped and its status in the warehouse.

• Other Dashboard functions – These involve reviewing data (spreadsheets, charts, etc.) shipment overviews, employee workloads, product layout and location, and other inventory data.

Once you can track these aspects of your freight, you will increase your own freight visibility and add greater value to your customers.

So, if you are looking for a way to relieve your complicated warehouse functions by organizing your operations, increasing your visibility through tracking and processing, and saving money, take a look at a warehouse management system.

We can help make your warehouse more efficient!: LET’S TALK