Companies today are always looking for ways to get ahead. They need to find ways to provide more value to their customers and trim the fat at the same time. Lean Management and Six Sigma principles can help them do just that. Lean Management and Six Sigma principles are an efficient, effective business philosophy that can guide corporate improvement, make companies stronger, and help companies differentiate themselves from their competition. Both Lean Management and Six Sigma methods work independently, but combined with one another they excel at helping organizations improve value, eliminate waste, create efficiency, and continually improve. Find out how these principles can help your business.

What are Lean Management Principles?

Lean Management is a philosophy of continuous improvement where companies maximize customer value while minimizing waste. It was first discovered in 1930s Japan and was perfected by the Toyota Motor Company in the 1980s. They discovered one of the most important things a company can do is to look at their product or service from their customer’s (or end-user’s) perspective to see what is of value to them. That way, the company can look over their own processes and determine what is worthwhile and focus on improving that. At the same time, they can determine what does not add value and eliminate it.

There are five principles that make up Lean Management. They include: Identify Value, Map the Value Stream, Create Flow, Establish Pull, and Seek Perfection. Each of these principles are part of a cycle that companies can use to constantly improve their processes or organization as a whole.

- Identify Value – This is from the customer’s perspective. Find out what parts of the product or service are valuable to the customer in relation to how it meets their wants or needs.

- Map the Value Stream – A company should understand a product or service’s entire life cycle from production through purchasing to the end of the life cycle. Understanding each step can guide companies on where the most value is and also determine the flow of the product/service’s life cycle.

- Create Flow – Flow is when a value stream operates smoothly. Any portion of the stream that is stagnant is wasteful and should be removed.

- Establish Pull – Companies should not produce anything until the customer asks for it.

- Seek Perfection – At this stage, all causes of defects or sub-par quality is eliminated from the manufacturing process.

Once a company determines how to create maximum value for their customers, they should look to eliminate waste. Waste can be any activity in a business that does not add value. The American Society for Quality provides a helpful list of eight types of waste businesses most often deal with, using the acronym DOWNTIME: Defects, Overproduction, Waiting, Non-utilized talent, Transportation, Inventory, Motion, and Extra-processing. Each of these aspects are common to business and are areas where most companies can improve.

- Defects – These can be flaws in products or mistakes made in other areas like shipping. Managers should evaluate where the flaws or mistakes take place; then they can develop and enact a plan to remove them.

- Overproduction – Companies do not need too much product on hand, only what the customer needs. These managers should perform strict research on past purchases, market trends, and customer requests to only produce what the customer needs.

- Waiting – This can affect nearly every step of the supply chain. One delay can ripple throughout the entire chain and slow the entire process. Totally lean companies operate with strict deadlines and with other companies that are able to meet them to avoid waiting completely. However, that is not always possible. So, companies should determine how much flexibility they can afford before the downtime becomes an issue and operate strictly to those standards.

- Non-Utilized Talent – These are knowledge, skills, attributes, or services that either company employees or vendors possess that businesses are not using that would strengthen the company and make it work more effectively. Solutions could be job changes or promotions for the right people, or revisiting with sales teams to find out how companies are missing out on vital services.

- Transportation – In logistics, trailer space is often what is wasted. Not enough product is shipped, or the wrong product is shipped, but the opportunity to move the right product is gone.

- Inventory – Much like overproduction, having too much inventory on hand can be an issue. Valuable warehouse space is used with each product and having too much of the wrong products or components prevents logistics managers from stocking the right products or components. Businesses should gauge a product or service’s pull and keep no more of that on-hand than what is needed.

- Motion – Especially in warehouses, is critical. Warehouses should be mapped out specifically to move the products most efficiently from the shelves to shipping. The highest velocity products should be the easiest to get to and to move. Aisles should allow easy movement for both personnel and machines, should be easily navigable, and be safe.

- Extra-Processing – This is adding more value to a product or service than the customer requires. This could include unnecessary details or features that the customer did not ask for or want (does not add value), that takes time away from making the product or performing the service the customer wanted. To be lean, effective logistics managers should find out exactly what their customer requires and do no more and no less.

Achieving leanness is not a simple task. It requires significant coordination throughout a company, and a buy-in spirit from each employee. Traditional Toyota Management System Theory states that any employee is able to make a change that affects the whole company. So, if a company achieves these lean principles, quality leaders at the American Society for Quality and others advise that they must extend this concept through their entire supply chain to reach their full potential. Companies in the supply chain not operating with lean management will surely stall the lean ones. Customers must evaluate their suppliers and subcontractors to make sure that they are acting at a similar leanness if the whole chain is to be effective and efficient.

What is Six Sigma?

Six Sigma principles are a data-driven approach to problem solving, and is aimed at eliminating defects in systems. According to ASQ, the term “six sigma” is a statistics reference to a process “within process limits ±3s from the center line in a control chart, and requirements/tolerance limits ±6s from the center line” and works out to fewer than 3.4 defects per million opportunities. Six Sigma looks to reduce process variation and increase process control, use teams for well-defined projects, and focus on methods like the DMAIC and DMADV processes.

Reduce Process Variation and Increase Process Control – Making sure everyone is working the same way.

- Each party working in the same system, causes less communication confusion, keeps the system is easier to update and maintain, and ensures the parties work with the same information.

Use Teams for Well-Defined Projects – Whenever a task, like continuous improvement, is needed, Six Sigma directs is practitioners to develop small, qualified teams to undertake the job.

- They are usually led by a quality professional, like a “Black Belt” certified member,

- They can work on the project on a part-time basis (by using the Team Method) or full-time basis (using the [Kaizen Event Method]) to blitz the project and complete it immediately.

Either way, these teams will use methods like the DMAIC or DMADV process to discover underlying process issues and correct them.

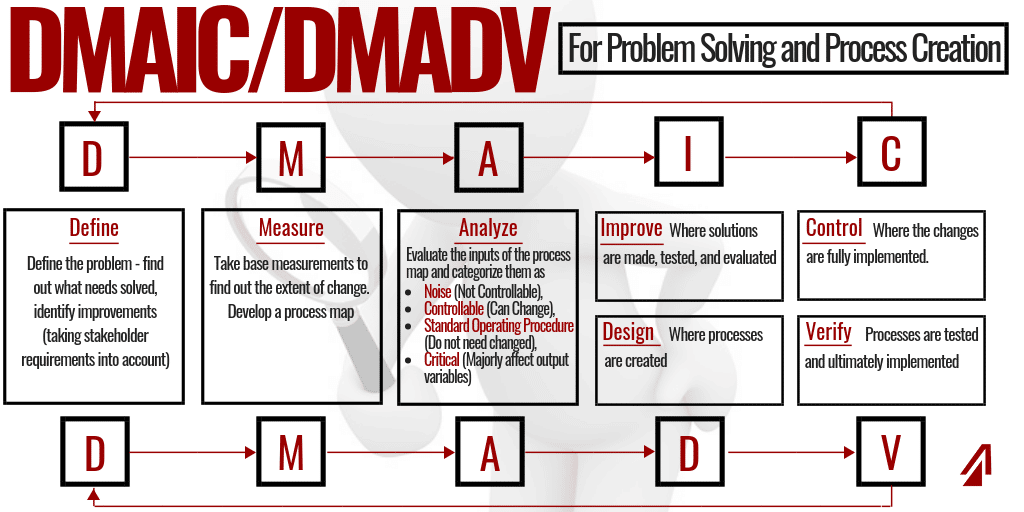

DMAIC and DMADV – These are common methods used for problem solving or process creation that logistics managers can use to improve their supply chains. DMAIC (Define, Measure, Analyze, Improve, Control) is primarily used for improving existing processes, whereas DMADV (Define, Measure, Analyze, Design, Verify) is most often used for new processes or existing processes requiring major improvement.

The first 3 steps are the same in each method.

- Define is the step where the problem solving team needs to define the problem. They need to know what needs solved, identify improvements, design goals, and take stakeholders’ requirements into account.

- Measure is the step where base measurements are taken so the process improvement team knows what gets changed. QA experts Townsend and Gebhardt said “A ‘problem’ is the distance between where you are now and where you could be,” so improvement teams measure a current baseline and also create a process map.

- Analyze is the last of the identical steps. During this phase the various inputs that are included in the process map are evaluated. These inputs are marked as Noise, Controllable, SOP, or Critical. Noise inputs are not able to be controlled because they are outside of the control of the improvement team. Controllable inputs can be adjusted. Standard Operating Procedures (SOP) are inputs that do not need changed, and Critical inputs are the ones that majorly affect the output variables. These inputs are often discovered in the Analyze step.

- Improve, Control – Improve is where solutions are made, tested, and evaluated, and Control is where the changes are fully implemented. Following Control, in the DMAIC process, the process can be repeated if further issues develop.

- Design, Verify – Design is where processes are created, and Verify is where the processes are tested and ultimately implemented.

These methods are extremely useful when dissecting a complex problem and determining the correct solution.

What is Lean Six Sigma?

Lean Six Sigma is bringing the two concepts together forming a team-focused managerial approach that seeks to improve performance by eliminating waste and defects. The idea came together in the 1980s in the United States and sought to combine the lean philosophy with Six Sigma tools. Some of the main focuses for Lean Six Sigma are the elimination of DOWNTIME, the use of DMAIC, and kaizen.

Kaizen is a Japanese word meaning “change for the better” or “continuous improvement.” It has two focuses – a business philosophy and an action plan. Kaizen philosophy helps companies continuously improve processes and involve all of the employees in the organization. With this approach, small changes are able to have large impacts on the company so improvement can be gradual and methodical. There are five basic tenets that make up the kaizen philosophy. These tenets are:

- Teamwork

- Personal Discipline

- Improved Morale

- Quality

- Suggestions for Improvement

With these ideas, kaizen seeks to eliminate waste, have good housekeeping, and standardize processes. Teamwork is essential for this philosophy to be successful; so, it is vital that every employee embrace the idea of engaging with the company and sharing ideas that could make the company better.

The second part of kaizen is the action plan. These action plans involve improving certain, specific portions of a company or process, and are often carried out in a method called a Kaizen Event. Kaizen Events are performed by small teams of QA employees, led by a professional quality leader like a “Black Belt,” and work to quickly detect areas of improvement and implement changes to improve quality. They often follow a cycle called PDCA (Plan, Do, Check, Act) to discover the problem and find possible solutions.

- Plan – This is where goals and objectives are established. Also, researchers will gather any resources they need to achieve the desired results and discover the risks or opportunities the changes will provide.

- Do – Researchers will first measure the current process for an accurate starting point. Then they will test the planned process changes.

- Check – The changes can be evaluated to determine the effect or impact of the change. Researchers will evaluate the changes against the beginning measurement and report on whether the change has been favorable.

- Act – Researchers can either fully implement the change or go back and make improvements to the change process.

PDCA can take place as often as needed to ensure that the correct changes are being made. Once the PDCA cycle has been completed to satisfaction, the kaizen event is ended.

The modern business climate requires constant improvement from companies in order to get ahead; and efficient, effective business philosophies like lean principles and six sigma can be just what they need to succeed. Lean principles are all about maximizing value for the customer while simultaneously removing waste from inside the company. Six Sigma offers helpful, specific tools that companies can use to streamline their processes and find useful solutions to problems. Separately, each is a strong formula for success, but combined, they are an unstoppable philosophy for change and improvement. The key is buy-in from everyone involved. Each employee should be willing to contribute ideas for change and have flexibility to change when needed. Not only should employees be involved, but the entire supply chain should be on-board for maximum efficiency. Once companies are able to focus on these principles they can become efficient, effective, and strong companies.