A Strategic Plan

- Reduce Spend

- Reduce CO2

- Reduce Damages

- Increase Efficiency

More planning equals

More saving

The Problem: A supplier was running an underutilized TL from McAllen, TX to a plant in Michigan because they needed TL transit.

The Solution: We recommended our “TL Through Consol” model to them to run the truck through our Laredo dock to fill out before heading North to Michigan. This allows us to invoice the customer only for the space that they utilize on the trailer yet they still receive TL transit.

The Savings:

This customer saves roughly 20% per load, roughly $32,000 per year

The Problem: A supplier ships dedicated truckloads of empty dunnage from a plant in Guanajuato to a supplier in the Midwest. ProTrans handles the cross dock operation for this customer along the US/MX border and recognized that every load was stacked 3 high but appeared to be able to be stacked 4 high.

The Solution: We recommended that the customer stack 4 high from their plant and the customer updated their loading guidelines for this supplier.

The Savings:

This change cut out roughly 24 loads per year. This is an example where ProTrans did not gain any additional revenue/margin (we actually lost a small amount of cross dock revenue), but the customer saved roughly $67,000 (25%).

The Problem: A supplier is paying a TL carrier to move multiple shipments from MX suppliers from the US/MX border to Greer, SC. Their carrier has been unable to cover loads recently and they have been moving as unplanned at a much higher cost.

The Solution: We reviewed the volumes and have offered to run this material through our shared consolidation network at TL transit. We priced this with LTL rates with a max of the TL rate so the customer should never pay more than their TL rate, but will pay much less every time the volume is less than a full trailer.

The Savings:

Estimated total save of $40,000 (25%).

The Problem: During the current transportation market in 2021, the carriers, other than increasing prices due to the high demand, have also reduced the vessel space allowed for all shippers. An Automotive Tier 1 supplier ships their European freight via a Shared Consolidation program with reliable transit times and costs for various plants, however, they also ship a full container to one of their plants located near the East Coast and that container is either underutilized in some weeks and in others there is more than one container worth of freight for that plant that makes the spend to go up in the long term.

The Solution: Our Procurement team was able to secure a container allocation for this particular customer for 6 TEU/week. A proposal was made to switch all their plants to a Buyer’s consolidation program which other than providing savings would improve the transit times for all plants in the program.

The Savings:

By implementing this change our customer is saving between 8% - 11% per week in their total freight spend. The most important saving is the Transit Time and service reliability, which in today’s market is invaluable.

The Problem: An Automotive Tier 1 supplier ships by Air 2 pallets from Europe to USA on a weekly basis. The average cost per shipment via Air is $3,131. This freight is considered vital and our customer does not want to jeopardize production or cause plant shutdowns.

The Solution: We recommended switching the transportation mode from Air to Ocean with a period of transition where there would be Air and Ocean shipments sent during the same weeks. Once the Ocean freight schedule becomes the new normal the Air shipment would be only used for emergencies.

The Savings:

By switching modes the customer has saved over $105,000/year. Similar changes were made to 4 other suppliers, resulting in saving of over $750,000/year.

The Problem: A large retailer with multiple distribution centers and stores across the United States requires coverage for all their containers imported from various Asia ports, mainly China, where shipping capacity has been reduced drastically since 2020 and during 2021. Their incumbent Freight Forwarder(s) can support these customers only up to a certain number of containers per week, and the rest of the containers continue to pile up at the origin ports waiting to be loaded on vessels.

The Solution: We have been contacted by this retailer (and several others) requesting support to move those containers. We have been successful at getting vessel space, bookings and get those containers moving with the support of our global partners.

The Savings:

Although Ocean Freight rates have skyrocketed since April 2020, and continue to increase due to the high demand, Covid restrictions, port congestions, etc. the savings, in most cases, don’t come via the freight spend but in the ability of the receiving plants to continue their production without plant shutdowns, which could cost much more than the current ocean premium services. We offer solutions with different modes, including AF, LCL, premium LCL, FCL, and premium FCL to ensure that the cargo continues its course in a timely manner.

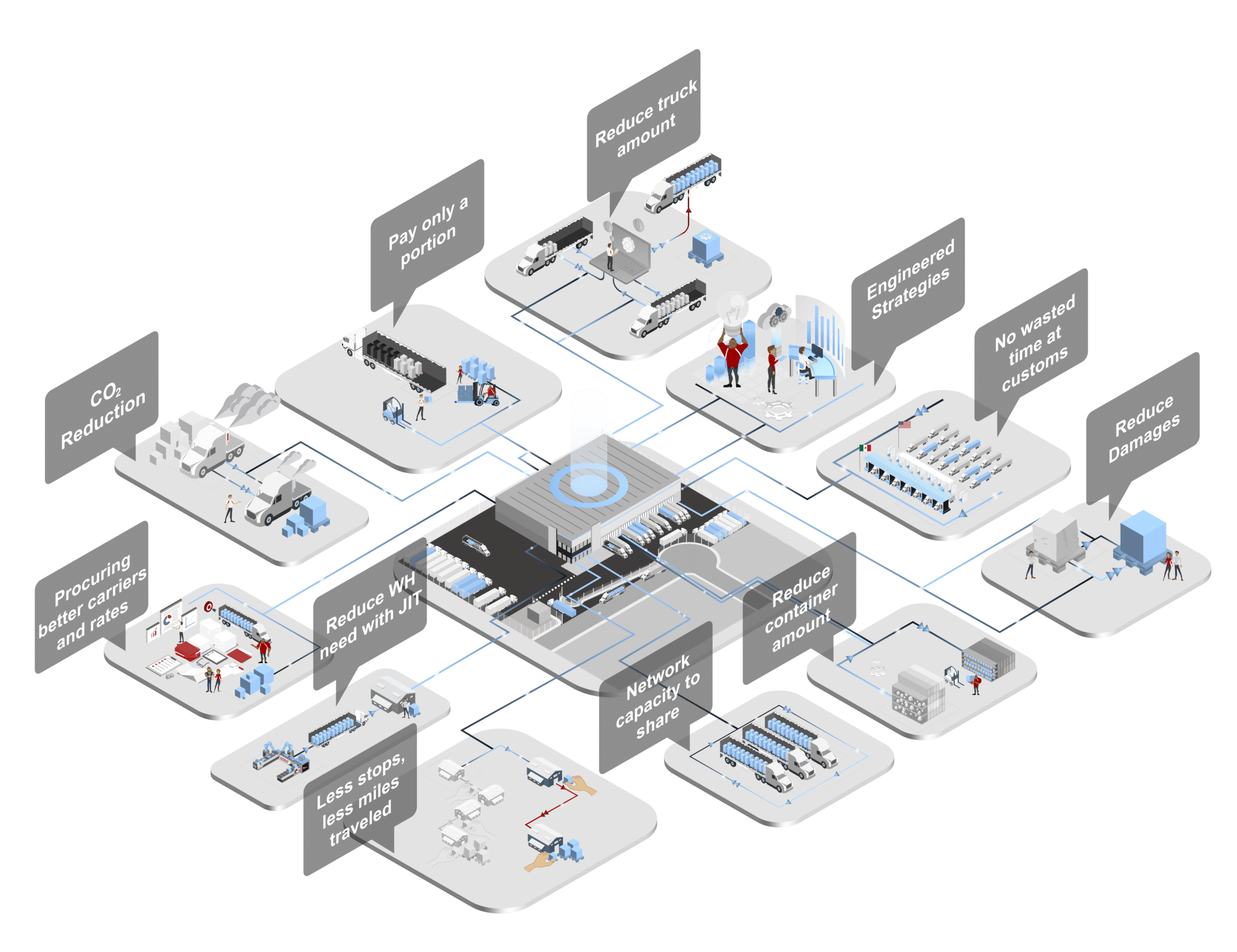

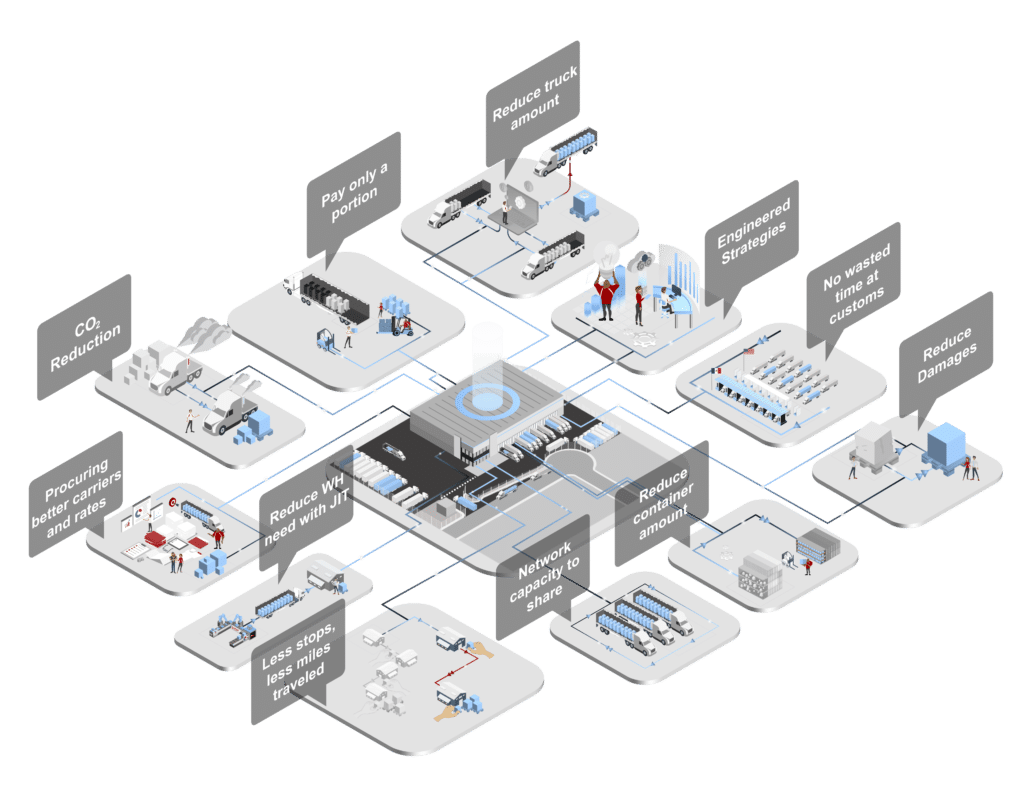

What does optimizing spend look like?

Optimize Capacity

Many companies don't utilize full trailer capacity. Our goal is to make sure you make the most of every trailer!

Reduce Trucks / Containers

Making the most of every trailer/container means you can use less trucks/containers to move your materials

Shorter LTL Distance

Because of our strategically located cross-docks and distribution centers, you won't have to pay for long LTL distances.

Less Damages

In our network, your materials experience less touch points therefore lessening the opportunity for damages. This results in less spend on damages.

Position Linehaul Pricing

With high capacity in our network, we always have the ability for you to fit right in and only pay for the space you need.

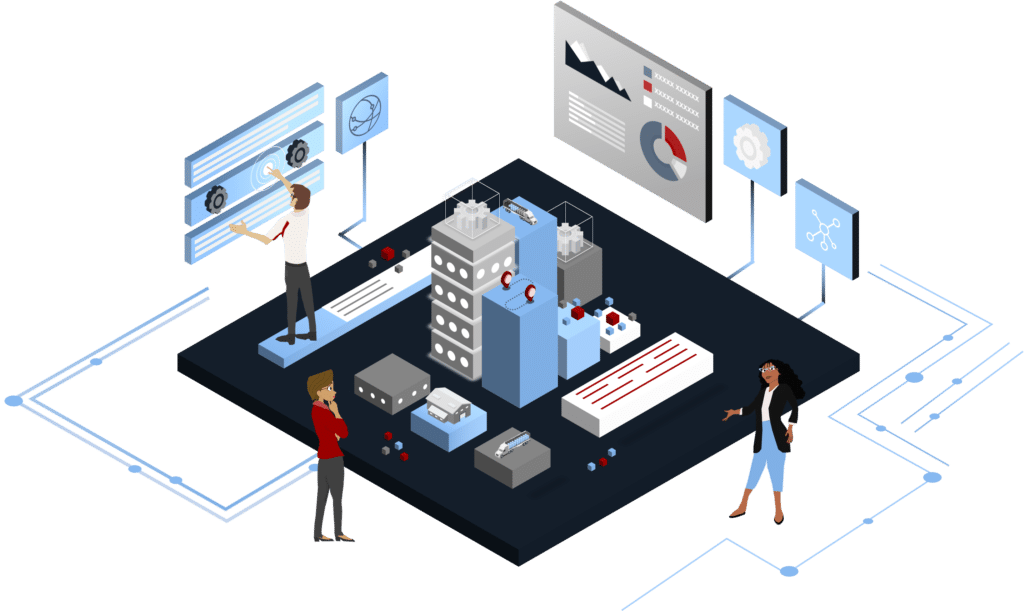

| We start by understanding and finding inefficiencies

1. Detailed Analysis

Our team of expert engineers comb through your data and look for inefficiencies and strategic opportunities that other 3pl providers cannot see.

| We take your logistics to the next level

2. Unique Planning

This is where the magic happens. Our teams come together and design a solution that creates efficient operations and reduces spend.

-

Capacity Optimization

One of the most crucial pieces to your plan is strategically pairing our networks and trailer organization with your shipment volume. This combination creates the spend reduction we see through LTL consolidation, LCL Consolidation, Truckload Optimization, and cost management efforts

-

Procurement

Our procurement team works to form the best carrier relationships possible. This not only results in lower costs, but overall better service.

| We execute your strategic plan

3. Full Management

Our Logistics experts stay on top of your supply chain to reach goals, resolve issues, and increase operational efficiency.

-

Plan Management

We ensure that we are living up to the plan that was set into place by hitting desired goals and milestones. Your plan will constantly be tracked with full attention to performance.

-

Account Management

We have set up regionally based teams to manage your supply chain. Our groups contain experts with different roles and vision:

1. Oversight (CCO and Director of Account Management

2. Tactical Operations (Key Account Managers, Account Logistics Managers)

3. Execution (Supply Chain Managers, Route Managers)

| We give you tools to control

4. Total Visibility

Our cutting edge technology suite, OPTIMIZ, is where we create your strategic solutions and where you see every single detail from a to z.

| We never stop finding you savings

5. Continuous Improvement

We continually look for new savings opportunities in your supply chain. We don’t simply want one savings change, we want to keep increasing the savings for you!