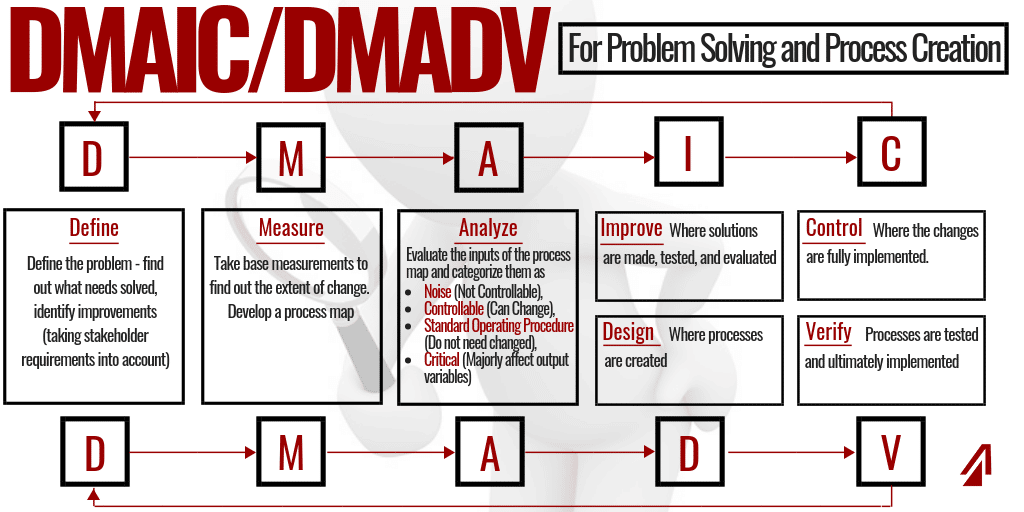

“Quality cannot be copied; there is no step-by-step cookbook that applies equally to all company situations and cultures,” say American Society for Quality experts with Ernst and Young. While there may be no blanket solutions for quality issues, root-cause analysis and problem solving tools like the DMAIC process are a good start. The DMAIC process is a data-specific quality process, taught by Six Sigma, that is often used for complex or high-risk problems. By breaking down the individual parts, and identifying when to use the DMAIC process, companies can use it to continually improve and achieve excellence in the best practices for their business.

D – Define

In his book, Evolution of Physics, Albert Einstein said, “The formulation of the problem is often more essential than its solution.” Defining the problem is often regarded as one of the most important steps in problem solving. One needs to know what the problem is before it can be solved. The Define stage is crucial to the DMAIC process because it is the basis of the problem and outlines the parameters of what is to be studied or changed. This phase is where the problem is laid out, improvements are identified, goals are designed for the improvements, and stakeholder requirements are taken into account. This is also where the problem-solving team is assembled.

ASQ refers to two different approaches to grouping the problem solvers in the Define stage – the Team method and the Kaizen Event method. The Team method is a slower approach where group members are led by skilled Quality or Process Improvement specialists. These problems are gradually solved over time while team members simultaneously handle other tasks. The progress is slow but thorough. The Kaizen Event method is more of a blitz approach where the team is specifically assembled to handle a problem quickly. These can often be handled in a week or so and have the benefit of rapid change. Both methods are effective when solving complicated issues.

M – Measure

QA experts Townsend and Gebhardt said “A ‘problem’ is the distance between where you are now and where you could be, no matter how good you are now,” and the Measurement phase of the DMAIC process reflects that. In this phase, the team already defined the problem and now need to track how far they are from solving it. To do that, they use trustworthy data to develop a current baseline. They use the baseline data to measure the progress made from that point onward. The baseline shows what is actually being done now and a process map can be created to help determine how the problem was caused initially.

Process maps are incredibly detailed charts noting each step of a complex system and the system’s progression from start to finish. Inputs are added at the beginning and outputs are the result. This is shown as Y = f(X); Y (Outputs) are a function of X(Inputs). These maps are primarily used to study variation in a process, identify improvement opportunities, and note the cause/effect relationship of one action to another in the system. The team utilizes several measurement standards to evaluate the process maps, and decide which ones work better. These can be modified as needed.

A – Analyze

In the Analyze phase, each of the inputs of the process maps are evaluated. They are broken up into smaller segments such as Noise, Controllable, Standard Operating Procedures, or Critical. Noise inputs cannot be controlled due to costs or other circumstance. Controllable inputs are factors that can be adjusted – giving them the nickname “knob” variables because they can be turned up or down. Standard Operating Procedures are inputs that do not require change nor testing. Critical inputs are those that majorly impact the output variables. These inputs are often not known when first creating the process map but are often identified in the Analyze phase. Critical inputs are often a roadmap back to the root cause of the problem.

I – Improve

The Improve phase is where the proverbial rubber meets the road. At this time, possible solutions are identified and evaluated. The root causes, highlighted by the critical inputs, are addressed or completely eliminated depending on the extent of the problem. This helps optimize the process and streamline it. The process map can be re-drawn as necessary to show the changes and allow the process to be re-evaluated. Then, a test of the changes can be implemented to see if they match the predictions from the process map. Once implemented, results from the changes are compiled by the problem solving group and measured against the baseline. Stakeholders can determine if the critical inputs are corrected to the customer’s needs. This is also where the problem solving team would determine if full implementation of the changes is functionally or financially possible.

C – Control

The final step in the DMAIC process, Control, is where the changes are fully implemented and are monitored long-term. The problem solving team can create standard operating procedures for the process and establishes measurement for future process performance. They will then train those in company to use the new process and document the training. Also, the problem solving team will consider other portions of the company where these improvements can be implemented as well. New adjustment can be made as needed.

By working together, 3PLs and carriers can achieve more than if each only looked out for its own interest. Synergy is a business buzzword that is nearly cliché, but its meaning is true. Stephen Covey, author of 7 Rules for Highly Effective People, says “Synergy is better than my way or your way. It’s our way.” By synergizing and aligning goals, both parties succeed and achieve more.

When to Use the DMAIC Process

The ASQ says that DMAIC is well suited for complex problems or those that pose high-risk to the company. They also recommend this for problems that are obvious with an existing process and for problems that are measurable. Some ASQ members feel like the DMAIC process can be used more frequently. ASQ member Carl F. Berardinelli states in his article “To DMAIC or Not to DMAIC” the process “should be the go-to method. Its discipline discourages a team from skipping crucial steps and increases the chances of a successful project.”

The DMAIC process is a problem-solving framework that carefully examines a problem step-by-step. Each subsequent phase builds on the last, instructing the team what to do next. It uses strict data methods and is customer focused and customer facing. It provides constant opportunities for evaluation and improvement. Legendary football coach Vince Lombardi said, “Perfection is not attainable, but if we chase perfection, we can catch excellence.” The DMAIC process is a continual improvement tool that can help companies pursue excellence. It is not a blanket solution to all issues, but it is an effective way companies can evaluate their underlying problems and tailor solutions specifically for them.