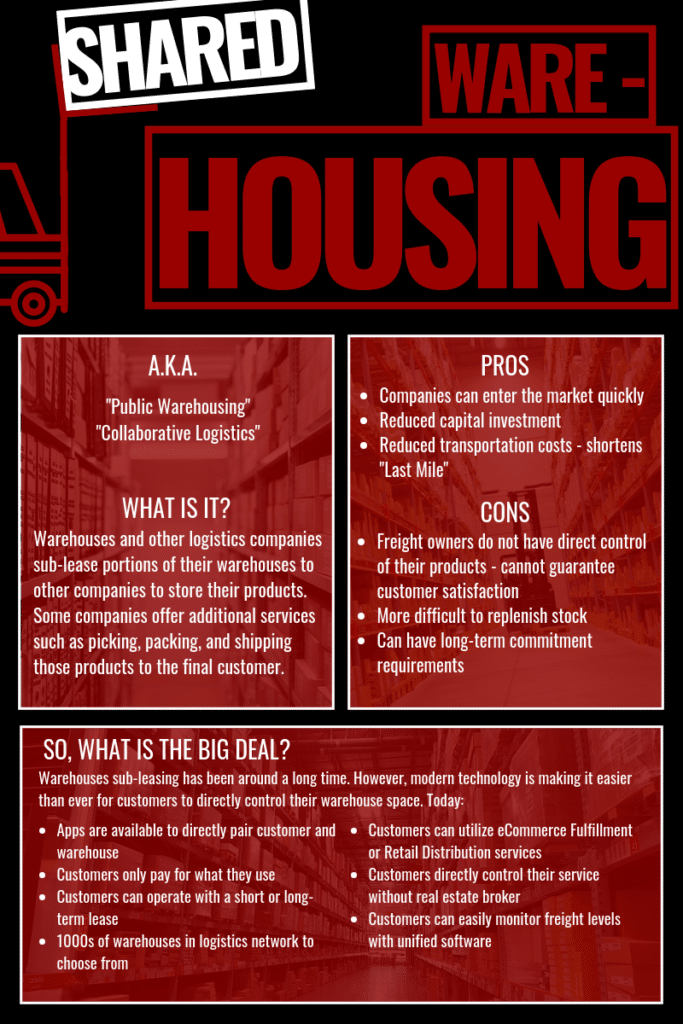

One of the most popular up-and-coming logistics technology trends strives to meet one of the fastest growing issues in logistics today – lack of warehouse space – by pairing customers and warehouses directly. Commonly called “uberization,” customers can use mobile apps to pair directly with suppliers on demand. The service comes as a result of reduced warehouse availability in major markets. According to real estate broker CBRE, markets like Seattle are facing just 5.6% entire warehouse vacancy and southern California entire warehouse vacancy is also below 5%. However, many companies in these regions have space to sublet to other companies available.

Sharing warehouses is not a new idea. Many logistics companies and 3PLs have been doing this for years. The technological advancement is in the direct contact from customer to supplier. Before, customers would work through brokerage firms and be limited to the space that the firms had access to – often by region. They would also be constrained with traditional contract fees and durations. But, with these new apps, customers are given the opportunity to expand to wider markets without being slowed by middlemen and without the astounding startup costs market entrances typically require. Customers work directly with suppliers through a web-based app and can tailor their service directly to their needs. These needs can vary from the standard long-term lease of 6 months or longer, or be more unconventional and have shorter durations. Other services like e-Commerce fulfillment or retail distribution are also available.

Once again, technology steps in to improve an old idea by looking at it in a new way. Sharing warehouses is a way to mitigate the warehouse shortages so many regions face, and on demand and direct contact service is a breakthrough in how to introduce suppliers to customers. That is why, this technology is one to watch.